Solutions

Real-world applications of AI-powered welding automation across industries.

Orbital Welding with a Positioner

Automate tank welding - even when the path drifts

Rotating a tank on a positioner gives you precision motion - but not a perfect seam. In real-world production, the weld joint often rises and falls slightly along the cylinder's axis as it rotates.

The Problem

Even 1-3 mm of axial drift can throw the torch off target. Laser profilometers often fail on reflective surfaces like aluminum.

How RocketWelder Solves It

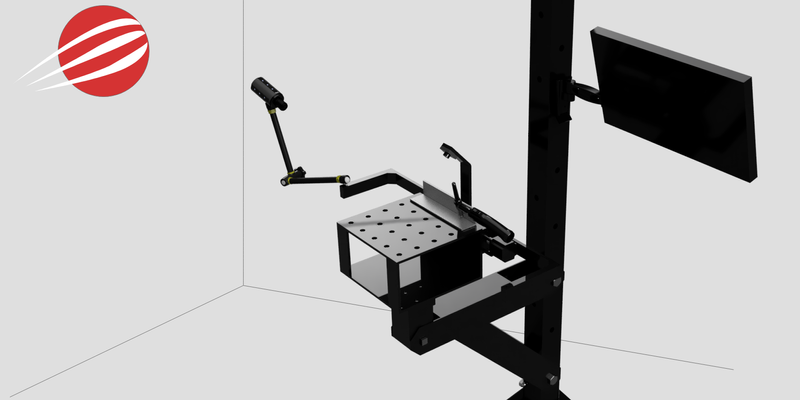

Full Automation for Long Structural Welds

Fully automated welding - no manual correction needed

Welding long components - like crane columns, beams, or frames - involves carriages and gantry arms that don't track the actual seam.

The Problem

Traditional systems follow external geometry, not the seam. Tolerance stack-up over long distances leads to inconsistency and rework.

How RocketWelder Solves It

Welding Training & Certification Station

Coming SoonAI-assisted feedback for the next generation of welders

Built for welding instructors, vocational schools, and certifiers.

Launching on Kickstarter

This is your chance to bring AI-powered weld tracking to your program.

Key Benefits